In today's fiercely competitive manufacturing landscape, achieving optimal cost efficiency and maximizing productivity are paramount. CNC (Computer Numerical Control) machine tools are the backbone of modern manufacturing, driving precision and automation. However, their performance is significantly influenced by the efficiency of the components within, and gear reducers play a critical, often underestimated, role. This article delves into how incorporating advanced gear reducer technology can unlock substantial cost reductions and efficiency improvements for CNC machine tool equipment, particularly relevant in today's era of Industry 4.0 and the ongoing push for smart manufacturing.

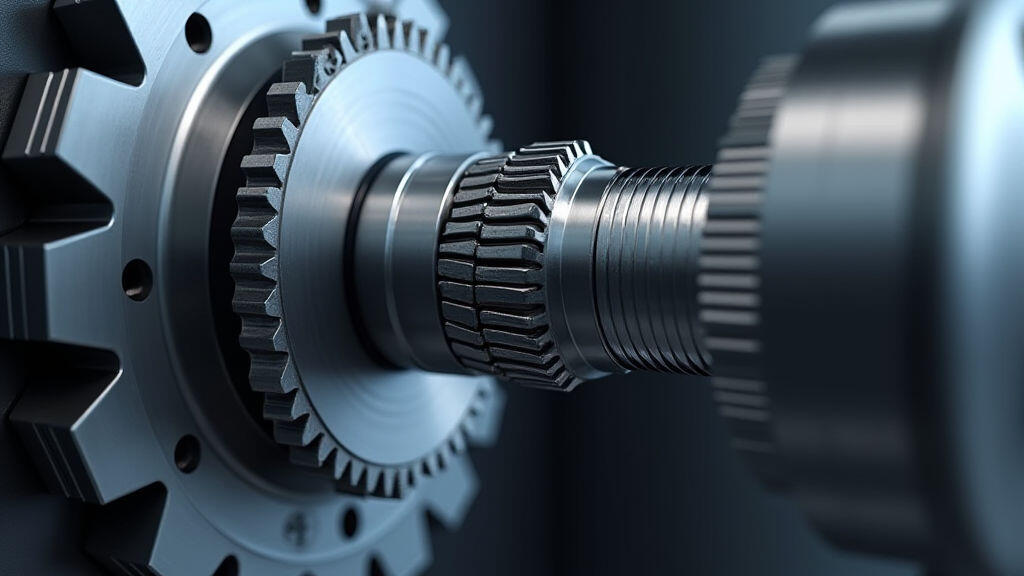

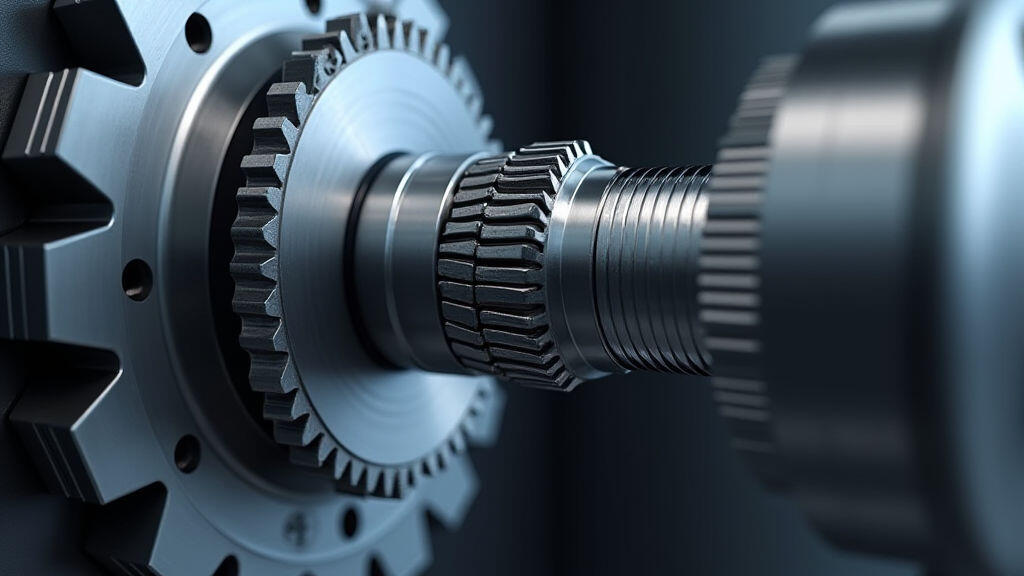

CNC machines rely on precise and controlled rotational motion. This motion is often generated by electric motors, but these motors typically operate at high speeds and low torque. Gear reducers bridge this gap, effectively lowering the rotational speed while simultaneously increasing the torque. This torque boost is crucial for driving heavy cutting tools, milling heads, and other components that require significant force. Without efficient gear reducers, CNC machines would be limited in their capabilities, unable to handle demanding tasks effectively and potentially facing premature component failure.

The impact of gear reducers on cost reduction stems from several key factors:

Beyond cost reduction, advanced gear reducers provide substantial efficiency gains:

The future of gear reducers in CNC machine tools is intimately linked to the broader trends of Industry 4.0. "Smart" gear reducers equipped with sensors and integrated control systems are emerging, providing real-time data on performance, condition, and energy consumption. This data can be used for predictive maintenance, optimized operation, and remote diagnostics. AI-powered algorithms can analyze this data to identify potential problems and proactively adjust parameters to maximize efficiency and minimize downtime.

Consider the growing importance of circular economy principles. Smart gear reducers can contribute by providing data to optimize the lifespan of components, reducing waste, and enabling more effective remanufacturing processes. Remote monitoring and diagnostics facilitated by smart reducers also allow for faster response times to potential issues, reducing the likelihood of costly repairs and minimizing disruptions to production. The integration of these technologies allows for a shift from reactive maintenance to proactive, predictive maintenance that significantly reduces operational costs and extends machine lifespan.

MES-Drive is at the forefront of developing these advanced gear reducer technologies. Our products offer a combination of high efficiency, durability, and smart features, empowering CNC machine tool manufacturers to achieve significant cost reductions and efficiency improvements.

Gear reducers are no longer simply a mechanical component; they are a critical enabler of efficiency, cost reduction, and precision in CNC machine tools. By embracing advanced gear reducer technology—particularly “smart” reducers that integrate with Industry 4.0 systems—manufacturers can unlock significant competitive advantages. In an era of increasing pressure on margins, constant innovation, and heightened environmental awareness, optimizing gear reducer performance is not just a strategic advantage—it's a necessity. Looking ahead, the development of AI-powered gear reducer management systems promises even greater gains in efficiency, predictive maintenance, and overall operational excellence. As the industry continues to embrace digital transformation, MES-Drive is committed to providing the innovative gear reducer solutions that will drive the next generation of manufacturing.

Leave A Reply

Your email address will not be published. Required fiels are marked